Additive Manufacturing

Additive manufacturing vs. injection molding. Manufacturing technologies used correctly.

ADDITIVE MANUFACTURING

INJECTION MOLDING © prodartis AG

INJECTION MOLDING © prodartis AG

WHEN IS ADDITIVE MANUFACTURING USED?

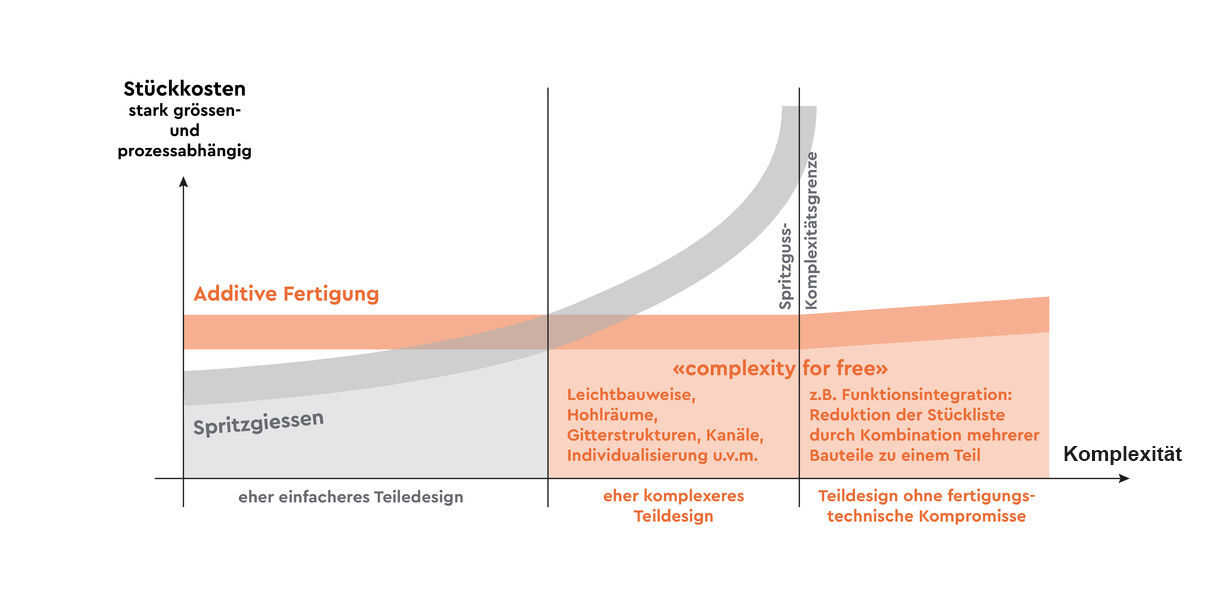

(compared to injection molding of parts that are not larger than a fist) While with injection molding, the unit cost increases the more complex the part geometry is, with additive manufacturing, the unit cost remains mostly unchanged. It is possible that, depending on the complexity, post-processing of additively manufactured pieces will become more involved and will result in slightly higher costs. At the same time, however, less material could be used, and the unit price could be slightly lowered despite increased complexity, for example, through a strong lightweight optimization.

While with injection molding, the unit cost increases the more complex the part geometry is, with additive manufacturing, the unit cost remains mostly unchanged. It is possible that, depending on the complexity, post-processing of additively manufactured pieces will become more involved and will result in slightly higher costs. At the same time, however, less material could be used, and the unit price could be slightly lowered despite increased complexity, for example, through a strong lightweight optimization.As a general rule: The more complex the part geometry becomes, the more it makes sense to use additive manufacturing.

WHEN IS ADDITIVE MANUFACTURING USED?

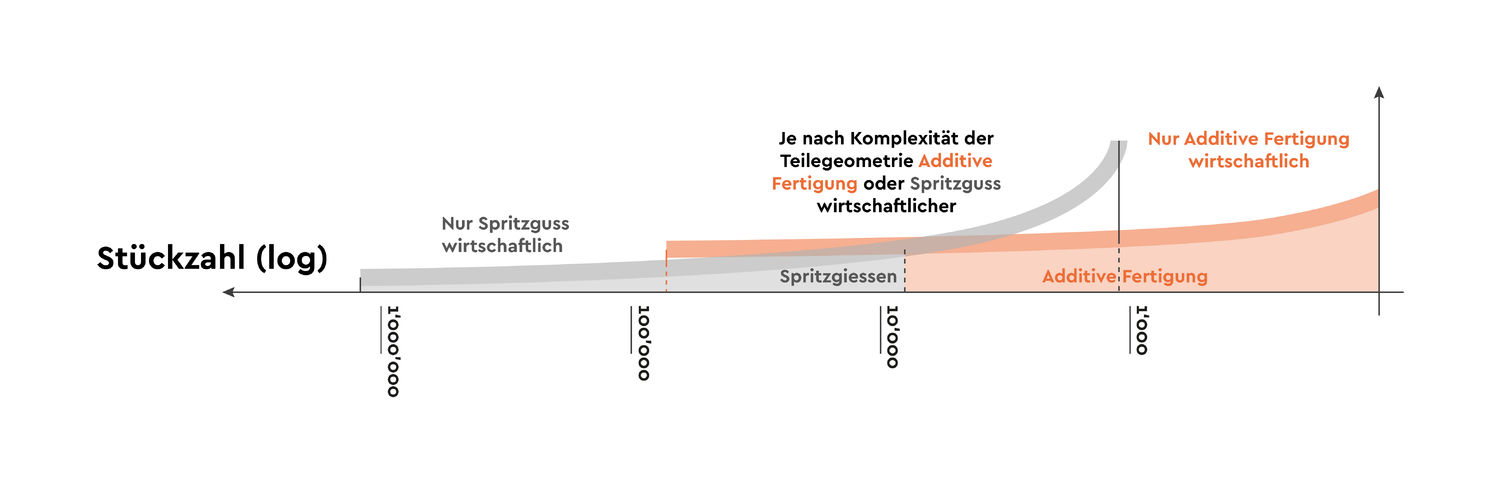

(compared to injection molding of parts that are not larger than a fist) Additive manufacturing is used economically for part counts ranging from 1 to several thousand parts or even for counts starting at 10,000 parts. Due to the high tool cost, injection molding is not efficient for lesser part counts but certainly for series with several 100,000 of parts.

Additive manufacturing is used economically for part counts ranging from 1 to several thousand parts or even for counts starting at 10,000 parts. Due to the high tool cost, injection molding is not efficient for lesser part counts but certainly for series with several 100,000 of parts.While with injection molding, the initially very high part count decreases quickly and considerably, with additive manufacturing, the unit cost also goes down, however, not as much.

As a general rule: The smaller the part count, the more economical additive manufacturing becomes.